China Wholesale Touch Free Automatic Car Wash Factory – CBK Automatic Water Recycling Equipment – CBK

China Wholesale Touch Free Automatic Car Wash Factory – CBK Automatic Water Recycling Equipment – CBK Detail:

CBK-2157-3T

Automatic Water Recycling Equipment Introduction

Product Display

i. Product Description

a) main use

The product mainly used for recycling car wash sewage.

b) Product characteristics

1. Compact structure and reliable performance

Adopt stainless steel box packaging structure, beautiful and durable. Highly intelligent control, all-weather unattended, reliable performance, and solved the abnormal operation of equipment caused by power failure.

2. Manual function

It has the function of manually flushing sand tanks and carbon tanks, and realizes automatic flushing by human intervention.

3. Automatic function

Automatic operation function of equipment, realizing full-automatic control of equipment, all-weather unattended and highly intelligent.

4. Stop (break) electrical parameter protection function

Multiple sets of electrical modules with parameter storage function are used inside the equipment to avoid abnormal operation of the equipment caused by power failure.

5. Each parameter can be changed as required

Each parameter can be changed as required According to the water quality and configuration usage, the parameters can be adjusted, and the working state of the equipment self-energy module can be changed to achieve the best water quality effect.

c) Conditions of use

Basic conditions for the use of automatic water treatment equipment:

|

Item |

Requirement |

|

|

operating conditions |

work stress |

0.15~0.6MPa |

|

water inlet temperature |

5~50℃ |

|

|

work environment |

environment temperature |

5~50℃ |

|

relative humidity |

≤60% (25℃) |

|

|

Power Supply |

220V/380V 50Hz |

|

|

inflow water quality

|

turbidity |

≤19FTU |

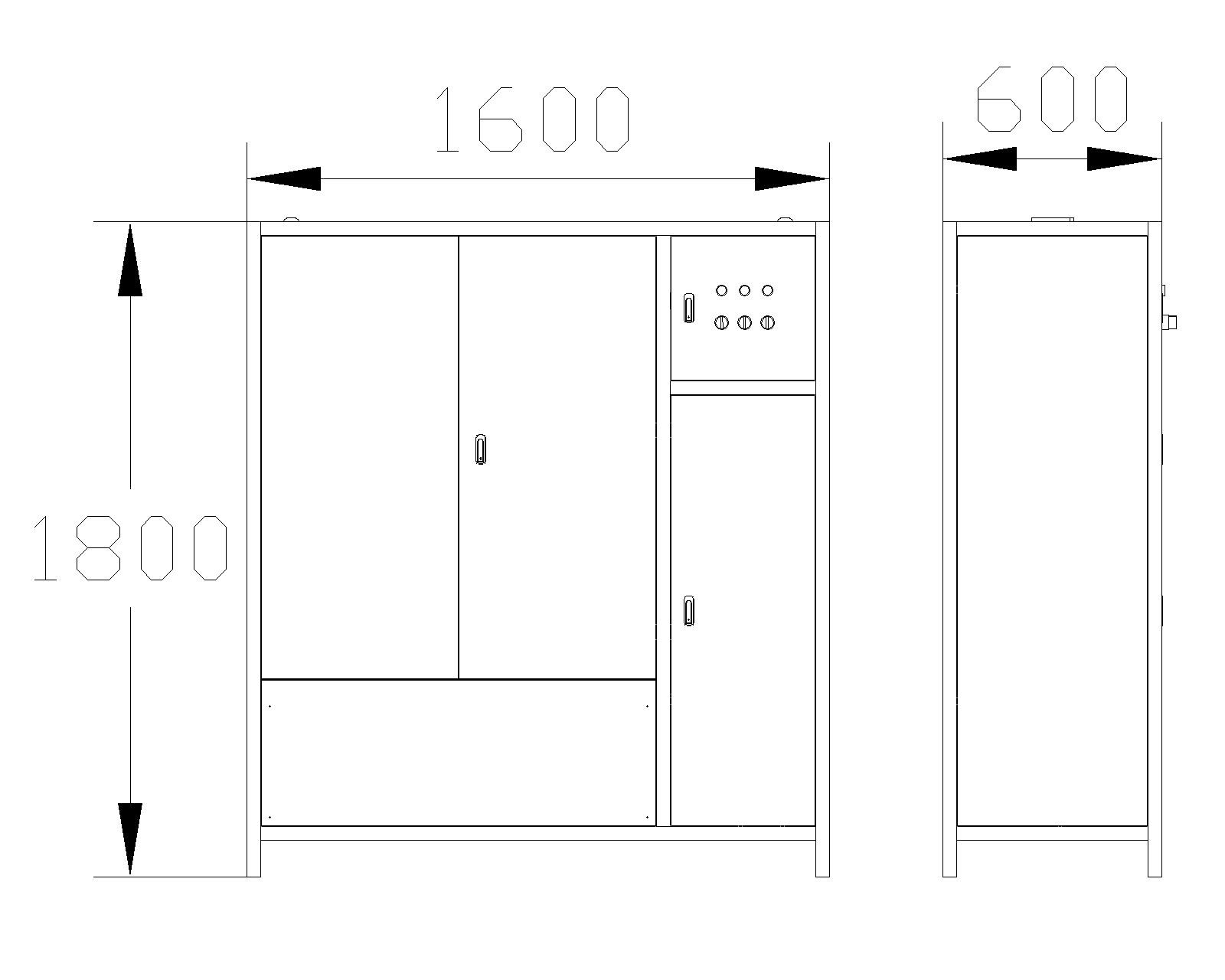

d) Outer dimension and technical parameter

ii. Product installation

a) Precautions for product installation

1. Ensure that capital construction requirements meet equipment installation requirements.

2. Read the installation instructions carefully and prepare all the tools and materials to be installed.

3. Equipment installation and circuit connection must be completed by professionals to ensure the normal use of equipment after installation.

4. Take-over shall be based on inlet, outlet and outlet, and shall comply with relevant pipeline specifications.

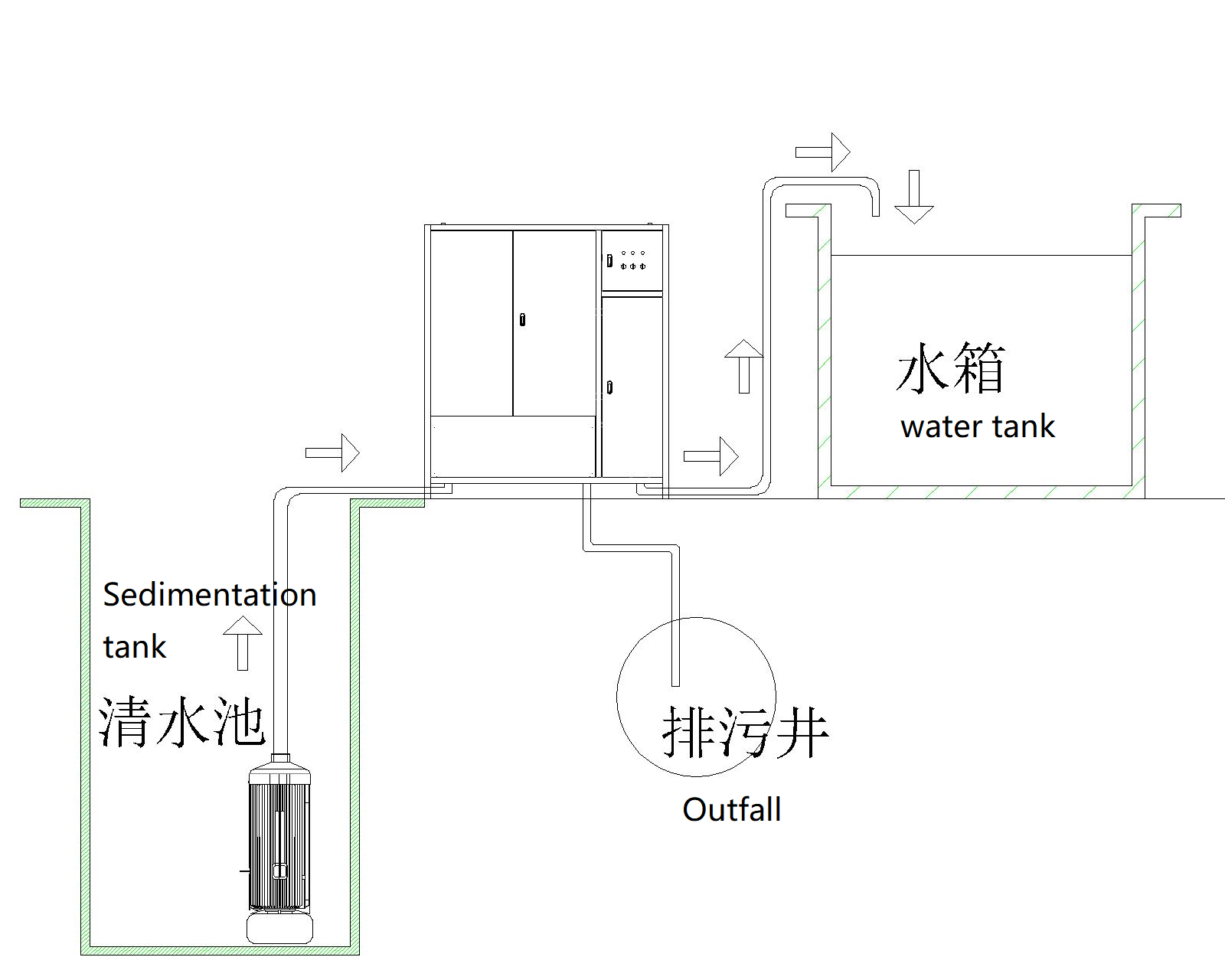

b) equipment location

1. When the equipment is installed and moved, the bottom bearing tray must be used for movement, and other parts are prohibited as supporting points.

2. The shorter the distance between the equipment and the water outlet, the better, and the distance between the water outlet and the sewage channel should be kept, so as to prevent siphon phenomenon and equipment damage. Leave a certain space for equipment installation and maintenance.

3. Do not install the equipment in the environment of strong acid, strong alkali, strong magnetic field and vibration, so as to avoid damaging the electronic control system and causing equipment failure.

5. Do not install equipment, sewage outlets and overflow pipe fittings in places less than 5 degrees Celsius and greater than 50 degrees Celsius.

6. As far as possible, install the equipment in the place with the least loss when water leakage occurs.

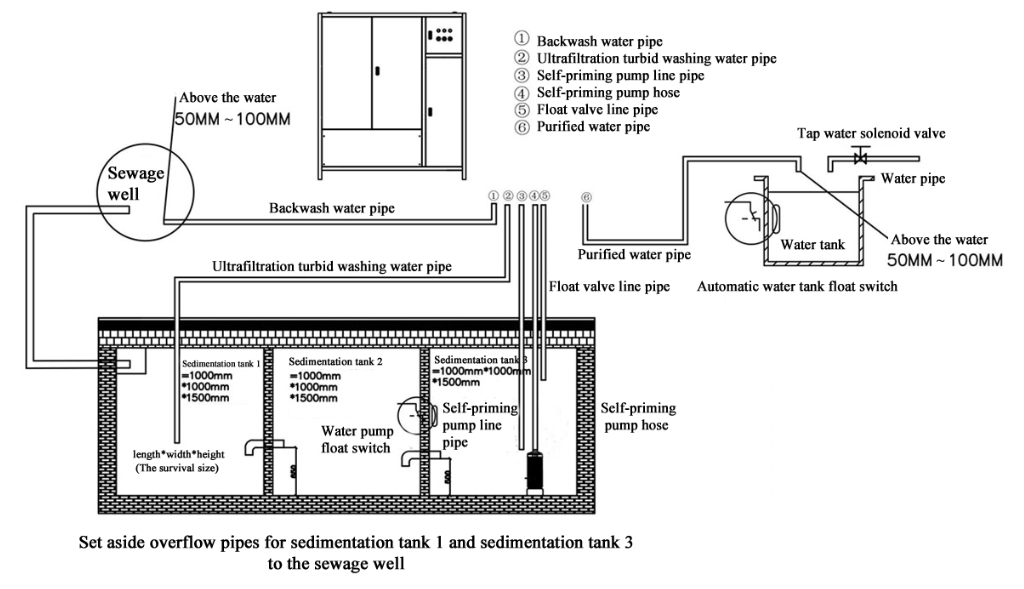

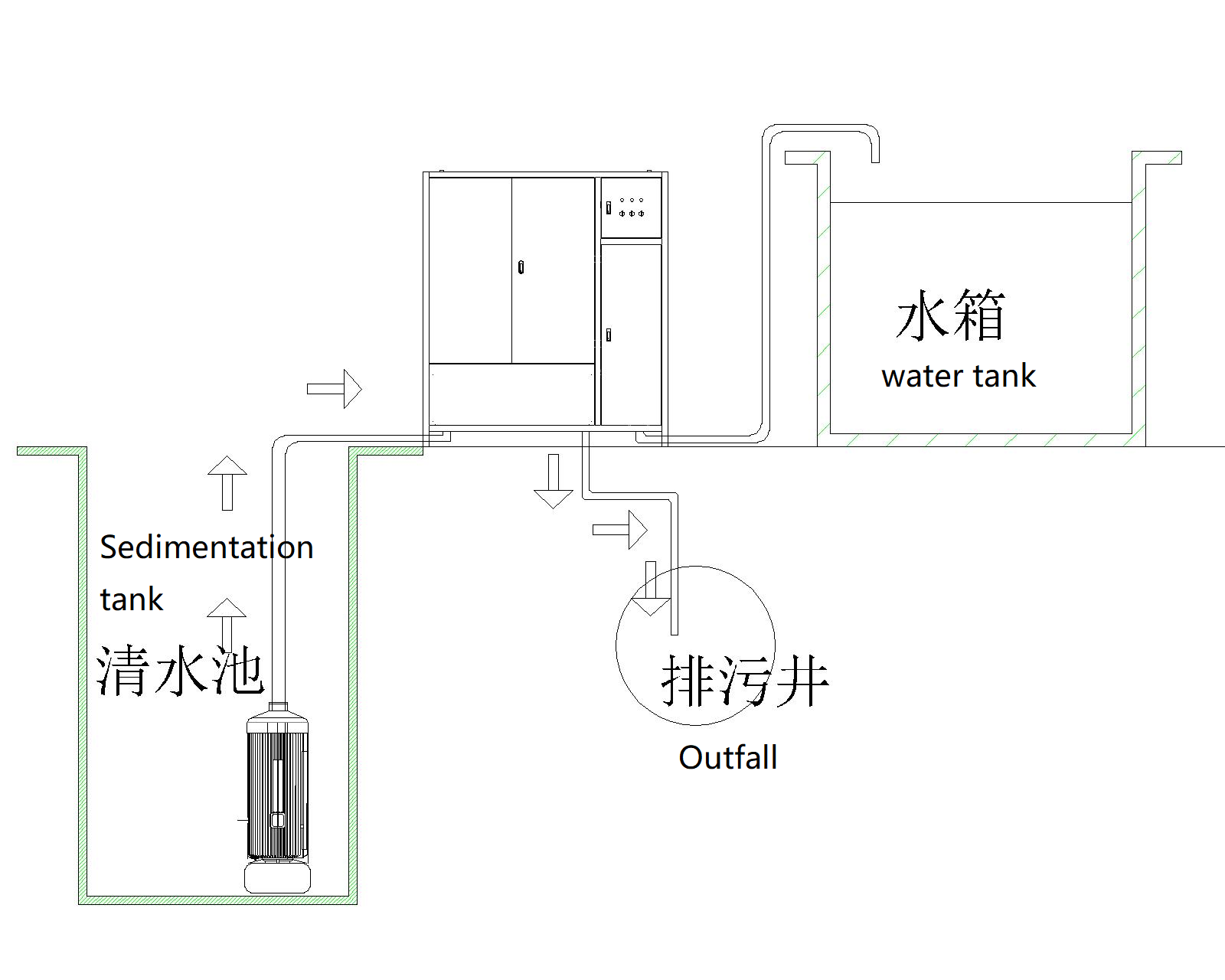

c) Piping installation

1. All water pipes are DN32PNC pipes, the water pipes are 200mm above the ground, the distance from the wall is 50mm, and the center distance of each water pipe is 60mm.

2. A bucket must be attached to the car wash water, and a tap water pipe should be added above the bucket. (It is recommended to install the bucket near the water treatment equipment, because the water pipe in the equipment needs to be connected to the water tank)

3. The diameter of all overflow pipes is DN100mm, and the pipe length is 100mm~150mm beyond the wall.

4. The main power supply enters the line and enters the host (installed capacity 4KW), with 2.5mm2 (copper wire) three-phase five-core wire inside, and a length of 5 meters is reserved.

5. DN32 wire casing, the transition tank enters the host, and 1.5mm2 (copper wire) three-phase four-core wire, 1mm (copper wire) three-core wire, and the length is reserved for 5 meters.

6. ⑤DN32 wire casing, sedimentation tank 3 enters the host, and 1.5m (copper wire) three-phase four-core wire is inserted inside, and the length is reserved for 5 meters.

7. ⑥DN32 wire casing, the sedimentation tank 3 enters the host, and two 1mm2 (copper wire) three-core wires are inserted inside, and the length is reserved for 5 meters.

8. Clear pool above must have a water pipe, has added the loss of water, to avoid causing the submersible pump burn.

9. The water outlet must have a certain distance from the water tank (about 5cm) to prevent siphon phenomenon and cause equipment damage.

iii. Basic Settings and instructions

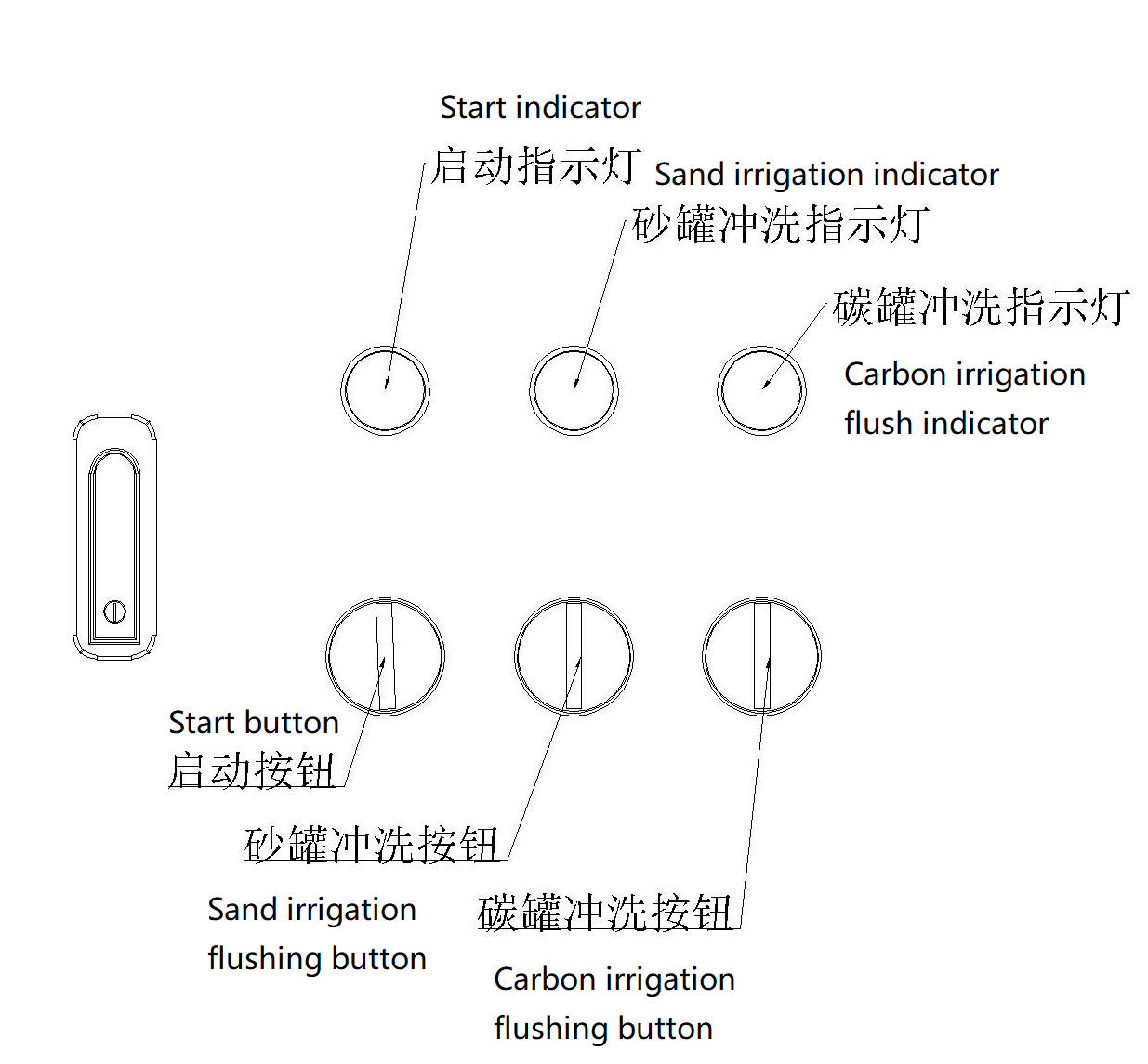

a) Function and significance of control panel

b) Basic setting

1. The factory set the backwashing time of sand tank to be 15 minutes and the positive washing time to be 10 minutes.

2. The factory set the carbon canister backwashing time to be 15 minutes and the positive washing time to be 10 minutes.

3. The factory set automatic flushing time is 21:00 p.m., during which the equipment is kept powered on, so that the automatic flushing function cannot be started normally due to power failure.

4. All the above function time points can be set according to the customer’s actual requirements, which is not fully automatic equipment, and it needs to be washed manually according to the requirements.

b) Description of basic settings

1. Check the running status of the equipment regularly, and contact our company for after-sales service in case of special conditions.

2. Clean PP cotton regularly or replace PP cotton (generally 4 months, the replacement time is uncertain according to different water quality)

3. Regular replacement of activated carbon core: 2 months in spring and autumn,1 month in summer it ,3 months in winter.

iv. application specification

a) Workflow of equipment

b) cashflow of equipment

c) Requirements for external power supply

1. General customers have no special requirements, only need to configure 3KW power supply, and must have 220V and 380V power supply.

2. Foreign users can customize according to the local power supply.

d) Commissioning

1. After the equipment installation is completed, carry out self-inspection, and confirm the correct installation of the lines and circuit pipelines before carrying out the commissioning operation.

2. After the equipment inspection is completed, the trial operation must be carried out to advance the sand tank flushing. When the sand tank flushing indicator goes out, the carbon tank flushing is carried out until the carbon tank flushing indicator goes out.

3. During the period, check whether the water quality of the sewage outlet is clean and free of impurities, and if there are impurities, perform the above operations twice.

4. Automatic operation of equipment can only be carried out if there are no impurities in the sewage outlet.

e) common fault and eliminating methods

|

Issue |

Reason |

Solution |

|

Device does not start |

Device power supply interruption |

Check whether the main power supply is energized |

|

The boot light is on, the device does not start |

Start button broken |

Replace the start button |

|

The submersible pump does not start |

Pool water |

Filling water pool |

|

Contactor thermal alarm trip |

automatic-reset thermal protector |

|

|

Float switch damaged |

Replace the float switch |

|

|

Tap water does not replenish itself |

Solenoid valve damaged |

Replace the solenoid valve |

|

Float valve damaged |

Replace the float valve |

|

|

The pressure gauge in front of the tank is elevated without water |

Blow-down cutoff solenoid valve is damaged |

Replace drain solenoid valve |

|

Automatic filter valve is damaged |

Replace automatic filter valve |

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for China Wholesale Touch Free Automatic Car Wash Factory – CBK Automatic Water Recycling Equipment – CBK , The product will supply to all over the world, such as: Sydney, Plymouth, Portugal, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don't hesitate to contact us. We will try our best to meet your needs.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.